templating

New worktops are a significant addition to any home. Installing these new worktops can drastically transform the appearance and functionality of your home for the better. But before your worktops can be installed, you must first go through the process of templating. This guide will provide you with knowledge of the templating process for stone worktops, including why it is done and how it is done.

What is Templating?

Templating is the process of developing a worktop template that will allow the fabricator to know the exact measurements of your new worktop. Without a template, the fabricator would not have an accurate idea of the exact shape and measurements the worktop requires.

What Do You Need to Do Before the Template is Made?

Before there can be any template made, there are a few things you will need to do. You must make sure that all units are installed and that all appliances are on-site. Without these two factors in place, you will not be able to make an accurate template. After you have completed these two steps, you can schedule templating.

How is Templating Done?

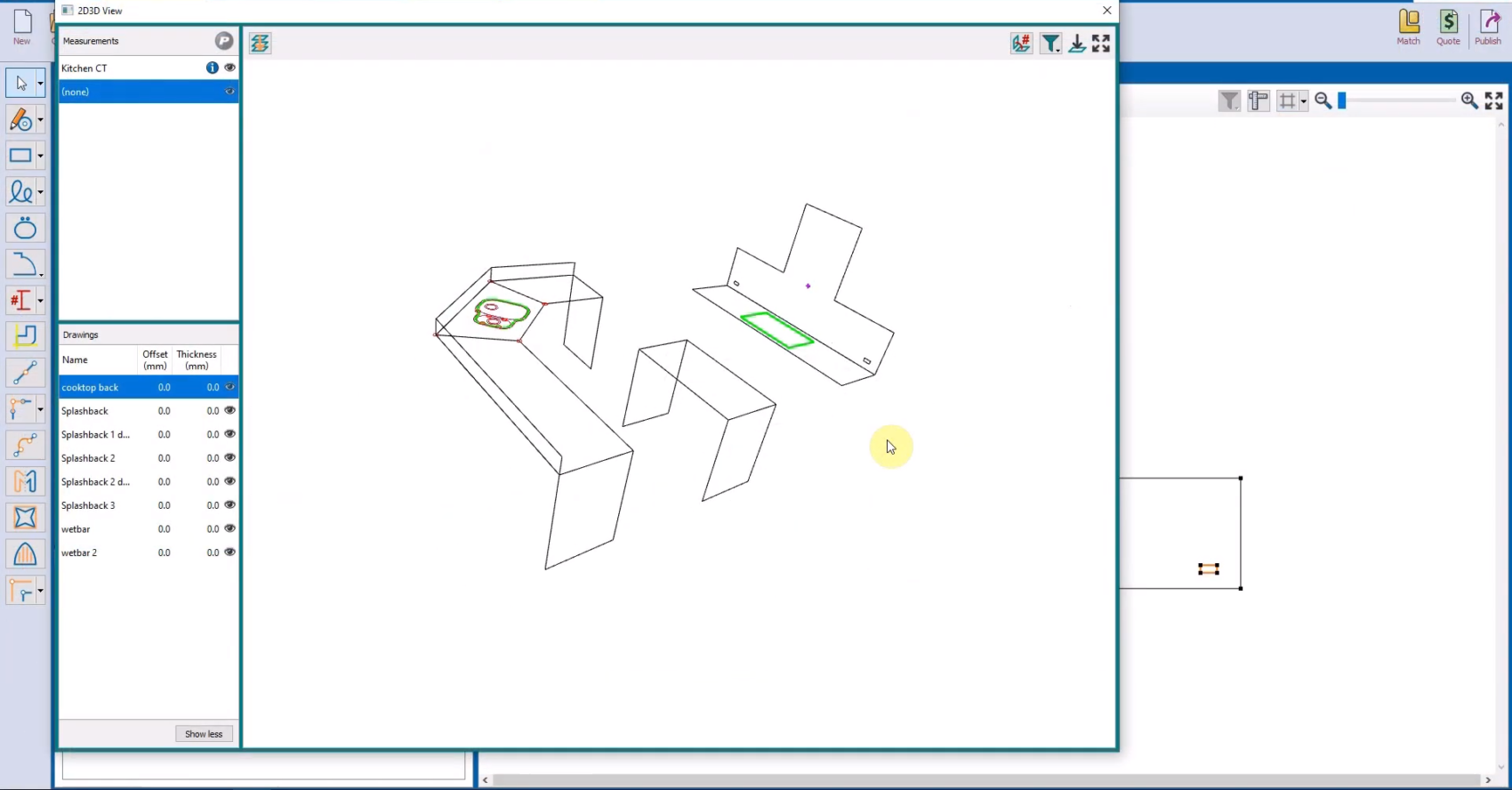

Once you have completed the prerequisites for templating and scheduled your appointment, a skilled technician will arrive to take the measurements. To measure, a high-intensity laser is pointed at the surface. This laser sends information to a computer, which records various points to create accurate dimensions. The technician will add in additional pertinent details, such as any overhangs, backsplashes, specialty cuts, cutouts for sinks and faucets or seams that need to be factored into the project. After this, the measurements are double-checked to make sure they are completely accurate. If the measurements are even a fraction of an inch off, it can drastically impact the project. Once the measurements are verified and saved, the computerised system sends them wirelessly to the fabrication facility. At the facility, the template is laid out on the stone’s surface. Following this, the stone can be cut using fabrication machinery.

HOW ARE WORKTOP TEMPLATES CREATED? STEP-BY-STEP

Step 1 A skilled technician arrives to take the measurements.

Step 2 A high-intensity laser is pointed at the surface. This laser takes specific measurements for the size of the worktop.

Step 3 The measurements taken by the laser are sent to a computerized system that records various points. This system is creating accurate dimensions.

Step 4 The technician will add in any specific details that are relevant to the project. Specific details include any overhangs, backsplashes, specialty cuts, cutouts for sinks and faucets, and seams that will factor into the project.

Step 5 After the measurements are recorded and the additional factors are noted, the technician will measure the surface again to ensure accuracy.

Step 6 Once the final information is saved in the system, it is sent wirelessly to the fabrication facility.

Step 7 Upon receiving the information, the fabricator will lay out the template on the surface of the stone.

Step 8 Lastly, the stone can be cut to the specific measurements your worktop requires.

POPULAR QUESTIONS

Yes you can use correx to template your own project but however having a professional templater do the job will ensure accuracy for a task that requires it. If the measurements for your new worktops are even a fraction of an inch incorrect, it can mess up the entire project.

Yes but bear in mind that both natural and engineered stone worktops are extremely heavy and should be handled with care. Depending on your project and the material you choose you may need to glue a colour matching adhesive to make the worktop seams inconspicuous.

After the templating process, and once you have confirmed the part of the stone you would like to use, the slab will be cut to the specific shape and measurements of your new worktop. After this, it will be delivered and installed in your home.